Radical Etching: Unconventional Etching Techniques with Steel

$400 for two full-day sessions (optional kit $55 extra)

Ready to Break Some Rules?

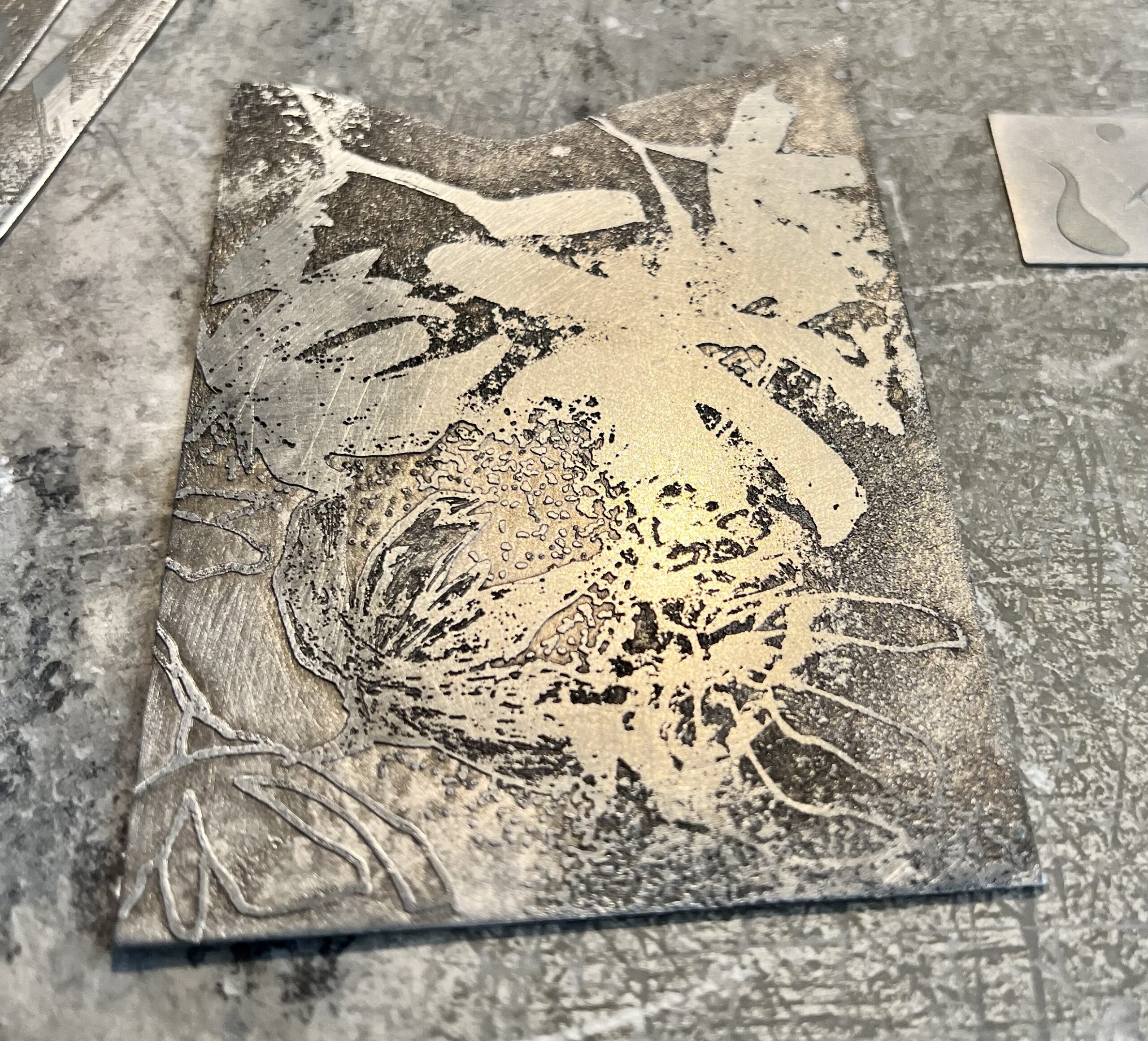

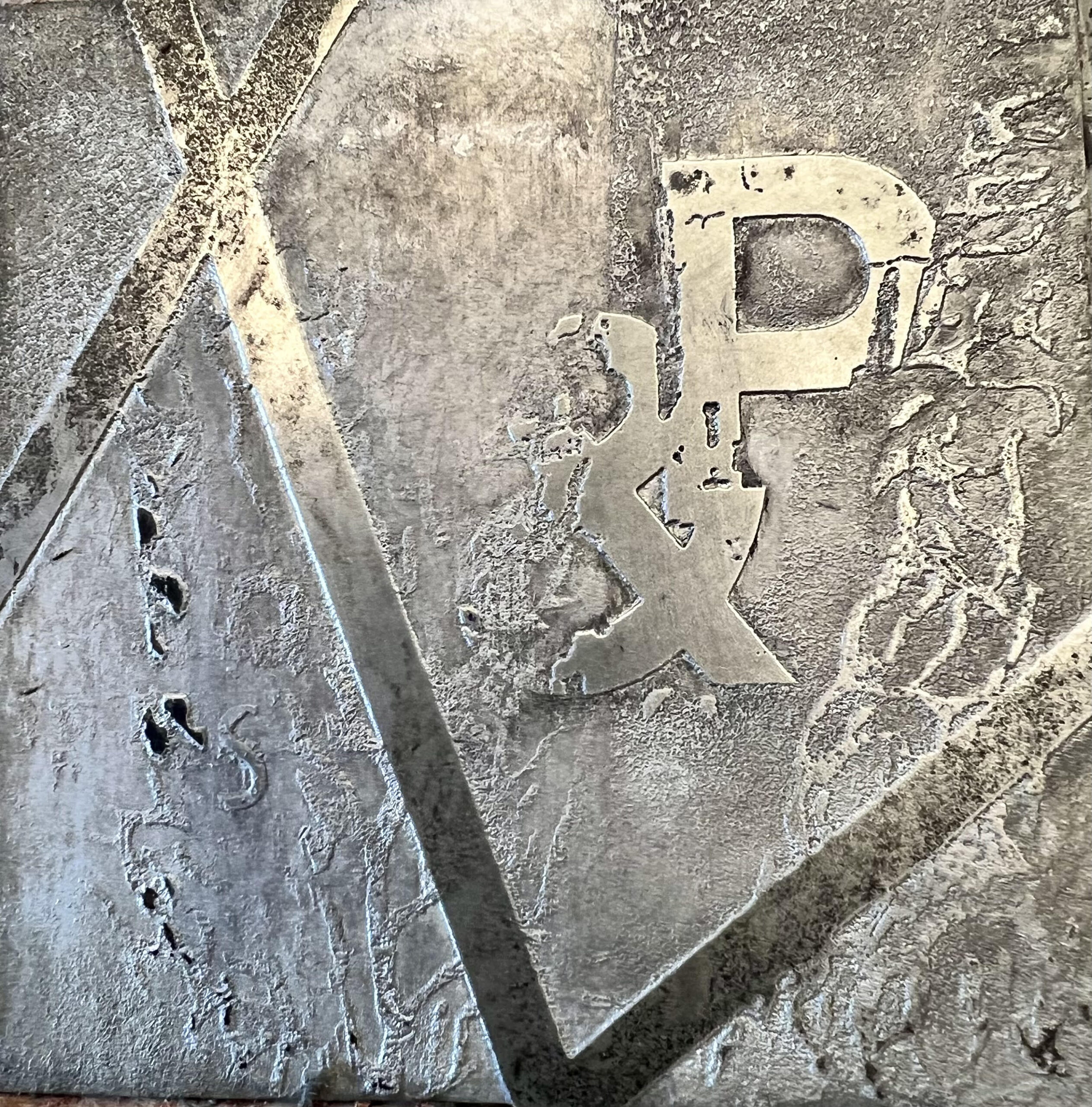

This workshop is all about letting go of traditional approaches to etching and instead exploring nonconventional ways to etch steel that produce fresh and exciting results and head-turning jewelry. We'll ditch the uninspired commercial artwork and create imaginative, completely original designs. Release your inner Jackson Pollack to explore out-of-the-box resists, like:- Oil paint brush, spray and splatters

- Dry transfers

- Decals

- Etching grounds (typically used in printmaking)

- Freeform hand cut stencils

- Tape, glue...in fact, anything that sticks to the metal and holds up in the etching solution!

What you'll learn:

- Basics of steel. Understand the characteristics of steel, how to buy steel, different forms of steel (sheet, wire, mesh and perforated sheet) and basics of working with steel (cleaning, cutting, sawing, filing, soldering, texturing, and forming).

- Resists for etching. Work with many different types of non-traditional resists for creating original designs for etching including oil paint, stencils and tape. You will learn to cut your own stencil resist using an electric heat pen. Understand the characteristics of steel, how to buy steel, different forms of steel (sheet, wire, mesh and perforated sheet) and basics of working with steel (cleaning, cutting, sawing, filing, soldering, texturing, and forming).

- Etching set-up. Etching set-up. Prepare the electro-etching station, including the etchant and power source. Use different power sources, including batteries and a rectifier.

- Etching process. Monitor the etching process to achieve the best results. Troubleshoot any problems. Explore layering and over/under-etching to achieve different creative effects.

- Patinas. Patinate your steel jewelry. We will work with several types of patinas, including heat and chemical in a wide range of colors and effects that add drama to the surface of etched steel.

- Sealers. Seal steel jewelry to protect it for years to come. We will work with different types of sealers, including oil, wax and lacquer.

DAY 1. Preparing the steel, setting up the etching station and applying the resists

10 am-4:30 pm PST (includes one hour break)

- Creative possibilities. Examine various examples of radical etches and discuss how they were achieved

- The basics. Introduce/review the basics of working with steel

- Overview of electro-ertching process. Understand the science and discuss pros and cons of various approaches.

- Setting up the etching station. Prepare the etching containers, materials and chemicals

- Non-traditional resists. Explore outside the box by using unconventional materials as resists.

DAY 2. Applying the resists, etching the metal, forming and finishing

10 am-4:30 pm PST (includes one hour break)

- Etching process. Discuss the standard process and then explore ways to manipulate it to achieve novel results.

- Troubleshooting. Anticipate and resolve any issues during the etching process.

- Design considerations. Incorporating etching into the design process.

- Finishing etched pieces. Forming, patinating and sealing.

Skill Level:

The workshop is suitable for all levels; however, basic metalsmithing skills such as sawing, soldering and forming will be helpful.

Kit ($55):

- Three sheets of 20g mild cold rolled steel, 5” x 8”

- Dry transfers

- Oil paint pen

- Battery holder with leads and alligator clips

- Three sheets of Oracal adhesive backed vinyl 6"x6"

- Plastic stencils

Student Provided Supplies:

The sources listed are merely suggestions and the materials may be available elsewhere.

- Wooden dowel, metal rod or heavy wire slightly longer than the wides side of the etching container (Note: This will be used to suspend the piece that you are etching.)

- Oil based paint (for example, Rustoleum). Small can and spray. Be sure it is oil based and not acrylic.

- Etching container (approximately 2-3-liter plastic or glass etching container). It is recommended that the container have straight sides and it should be taller than it is wide.

- Aluminum or copper sheet 20g or thicker, to be used as a cathode during the etching process. It should fit inside etching container, be at least half the width of the longer side of the container and tall enough to extend approximately one inch extending from the top of the container.

- Copper sulphate, Can be purchased as Root Killer in hardware stores and plant nurseries (check label to ensure it is cupric sulphate pentahydrate) of in powder form (Amazon) You will need 3/4 cup per liter of water in the etching container.

- Non-iodized salt for etching solution (Grocery Store). You will need 3/4 cup per liter of water in the etching container.

- Two D batteries (plus extras as backup) (Grocery Store, Hardware Store)

- Small paint brushes (cheap paint brushes) (Michaels)

- Gun bluing (I like Oxpho Blue.) (Amazon, Brownells)

- Steel wool (fine) (Drug Store, Grocery Store)

- Wax. Your choice of clear Metal Wax from Sculpt Nouveau OR Bowling Alley Wax from Amazon

- Rectifier (Power Supply).• Rectifier—inexpensive powder supply (Amazon $79 or Amazon $59) A cheaper one is also available from Amazon $37 with favorable reviews but I have not tested it.

- NanoBlades (PepeTools) or Sierra saw blades (Contenti) are recommended for steel. 3/0 and 4/0

- Ballistol Lubricant and Oil for Steel (Amazon)

Basic Tools & Supplies

For supplies, materials and tools that you will need to provide for all classes, please refer to the basic list for tools and supplies needed for working with steel in the pdf below. As with the list of class-specific supplies (above), many of these are items that you may have on hand. Note that the sources shown are merely examples. Many different vendors can be sourced for these products.

Basic Tools and Supplies for Working with Steel »